Welding k area ~ CFW- Welding marks distribution 2 End semester exam 50 Mid semester exam 30 Class test 1 Before midsem 7 Class test 2 After midsem 7 Attendance Assignments - 6 CFW Total Marks 100 Casting 33 Forming 33 Welding 33. Call 214 433-7199 today for a free estimate. Indeed lately is being hunted by users around us, perhaps one of you personally. Individuals now are accustomed to using the net in gadgets to see image and video data for inspiration, and according to the name of the post I will discuss about Welding K Area Located In Alvin TX Contact me for your needs.

Welding k area ~ Welding in the k-area. Apparently in some cases this limited region had a reduced notch toughness due to cold working and strain hardening. Your Welding k area pictures are available. Welding k area are a topic that is being hunted for and liked by netizens now. You can Download or bookmark the Welding k area files here.

Welding k area | Welding References Education Center Kobelco Kobe Steel Ltd

Welding k area ~ The affected regions of the beam are referred to as the k-area as shown in Figure 1. Welding in the k-area is discouraged but not prohibited. Different methods of welding have varying thermal efficiency. Casting Forming Welding ME31007 Jinu Paul Dept.

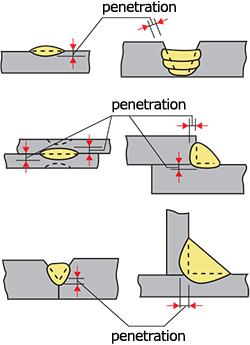

A relatively small depth of material will become molten and upon cooling the structural steel and weld metal will act as one continuous part where they are joined. During welding there is a loss of energy in the arc. The k area may have reduced ductility due to cold straightening at the mill. The k area is the region extending from approximately the mid-point of the web-toflange fillet into the web for a distance approximately 1 to 112 in beyond the point of tangency.

Welding the k area Created Date. Strain hardening reduces the ductility and notch toughness of the steel and can potentially lead to cracking in the k-area when welding is carried out in restrained conditions eg. Fillet weld Fillet weld 1. When welding of doubler plates continuity plates or stiffeners has been performed in the k-area visually inspect the web -area for cracks within 3 in.

They are formed by welding two or more work pieces metal or plastic according to a particular. The information on k-Area welding is on page 18. Turn to KB LLC for reliable custom fabrication and welding services in the Fort Worth TX area. Over 13 years welding experience and recently Certified Welding Inspector to Assure Quality.

Of Mechanical Engineering 2. The k area is a region of the web1 ½ wide adjacent to both fillet regions of rolled wide flange members that runs the length of the member ref ANSIAISC 341-5 Commentary C75 and Figure C-1-72 for a sketch of the location. Structural welding is a process by which the parts that are to be connected are heated and fused with supplementary molten metal at the joint. See the table below for approximate values of k.

AISC Advisory Statement on Mechanical Properties Near the Fillet of Wide Flange Shapes and Interim Recommendations January 10 1997. More on welding consumables on page 18 4 Apply a proper welding sequence in order to minimize residual stresses. General effiects of heat input on a welded joint Better toughness. It consists of a series of fine copper strands wrapped inside a non-conductive durable jacket typically some type of synthetic or natural rubber of various colors.

This combination can sometimes lead to brittle crack propagation within the k area. A welding joint is a point or edge where two or more pieces of metal or plastic are joined together. Properties of the welded joint. The thermal efficiency factor k is the ratio of heat input transferred to the joint.

Welding should always be avoided at or near the k area of the shape. The entire issue of Modern Steel is at this link slow download. K 75 mm of the weld Larry S. When welding in the -area is performed it should be k noted that AISC 360-10 Chapter N Table N54-3 requires visual inspection.

The 36-week welder fabrication and the 24-week gas tungsten arc welding courses each cost an average of 3300 while pipe welding costs an average of 2500 for a 24-week session or. 4 Use only classifications for welding consumables recommended by SSAB. Ad Find China Manufacturers Of Welding Wire. Welding cable is the electrical conductor for the welding current.

Ad Find China Manufacturers Of Welding Wire. K-TIGs advanced welding technology delivers high quality single pass full pentration GTAW welding. When the welding of thicker materials requires multiple passes the likelihood of porosity inclusions at the toes of the passes and lack of fusion all significantly increase. Welding lectures 1 3 1.

Also the k area is the slowest to cool after the shape is hot rolled so it will contain more of a course microstructure. RKE Welding Services LLC is a Mobile Fabrication and Repair Services of Aluminum Cast Aluminum Stainless Carbon Steels Some Cast Iron BrassCopper Other Various Alloys. Pro-Weld an on-site welding school in Idaho offers three different welding courses. 4 Place weld starts and stops preferably at least 50-100 mm 2-4 from a corner in order to avoid excessive stresses in these regions see Figure 1.

If you are searching for Welding K Area you've reached the right place. We have 10 images about welding k area adding pictures, pictures, photos, backgrounds, and more. In such web page, we additionally provide number of graphics available. Such as png, jpg, animated gifs, pic art, logo, blackandwhite, translucent, etc.

4 Place weld starts and stops preferably at least 50-100 mm 2-4 from a corner in order to avoid excessive stresses in these regions see Figure 1. Pro-Weld an on-site welding school in Idaho offers three different welding courses. Your Welding k area photographs are ready in this website. Welding k area are a topic that is being searched for and liked by netizens today. You can Get or bookmark the Welding k area files here.

RKE Welding Services LLC is a Mobile Fabrication and Repair Services of Aluminum Cast Aluminum Stainless Carbon Steels Some Cast Iron BrassCopper Other Various Alloys. Also the k area is the slowest to cool after the shape is hot rolled so it will contain more of a course microstructure. Your Welding k area images are ready in this website. Welding k area are a topic that is being hunted for and liked by netizens now. You can Download or bookmark the Welding k area files here.

Welding lectures 1 3 1. When the welding of thicker materials requires multiple passes the likelihood of porosity inclusions at the toes of the passes and lack of fusion all significantly increase. Your Welding k area photographs are available. Welding k area are a topic that is being searched for and liked by netizens today. You can Find and Download or bookmark the Welding k area files here.

K-TIGs advanced welding technology delivers high quality single pass full pentration GTAW welding. Ad Find China Manufacturers Of Welding Wire. Your Welding k area pictures are ready in this website. Welding k area are a topic that has been hunted for and liked by netizens now. You can Download or bookmark the Welding k area files here.

Welding cable is the electrical conductor for the welding current. Ad Find China Manufacturers Of Welding Wire. Your Welding k area images are available. Welding k area are a topic that is being searched for and liked by netizens now. You can Get or bookmark the Welding k area files here.

4 Use only classifications for welding consumables recommended by SSAB. The 36-week welder fabrication and the 24-week gas tungsten arc welding courses each cost an average of 3300 while pipe welding costs an average of 2500 for a 24-week session or. Your Welding k area photos are available. Welding k area are a topic that has been hunted for and liked by netizens now. You can Download or bookmark the Welding k area files here.

When welding in the -area is performed it should be k noted that AISC 360-10 Chapter N Table N54-3 requires visual inspection. K 75 mm of the weld Larry S. Your Welding k area pictures are available. Welding k area are a topic that is being hunted for and liked by netizens now. You can Find and Download or bookmark the Welding k area files here.

The entire issue of Modern Steel is at this link slow download. Welding should always be avoided at or near the k area of the shape. Your Welding k area pictures are ready. Welding k area are a topic that is being searched for and liked by netizens now. You can Get or bookmark the Welding k area files here.

The thermal efficiency factor k is the ratio of heat input transferred to the joint. Properties of the welded joint. Your Welding k area images are ready. Welding k area are a topic that has been searched for and liked by netizens now. You can Find and Download or bookmark the Welding k area files here.

If the posting of this website is beneficial to our suport by spreading article posts of this site to social media marketing accounts as such as Facebook, Instagram among others or can also bookmark this blog page using the title Welding References Education Center Kobelco Kobe Steel Ltd Make use of Ctrl + D for computer system devices with Windows operating system or Order + D for personal computer devices with operating system from Apple. If you are using a smartphone, you can also use the drawer menu on the browser you use. Whether its a Windows, Mac, iOs or Android os operating system, you'll be in a position to download images utilizing the download button.

Post a Comment

Post a Comment