Preheat temperature for welding carbon steel ~ Pre-Heat Calculator to EN1011 Part 2 - Non Alloyed And Low Alloy Steels. This means that no HAZ cracks but weld metal cracks were observed in the non-preheat condition while they were stopped at 50Ž preheating. Indeed lately has been searched by consumers around us, perhaps one of you. People now are accustomed to using the internet in gadgets to see video and image information for inspiration, and according to the name of the post I will talk about about Preheat Temperature For Welding Carbon Steel Preheat a large enough area around the weld joint to ensure the proper temperature is maintained throughout welding.

Preheat temperature for welding carbon steel ~ Second preheating results in removing moisture condensate before welding. Page last updated 13 April 2002. Your Preheat temperature for welding carbon steel pictures are available in this site. Preheat temperature for welding carbon steel are a topic that is being searched for and liked by netizens today. You can Download or bookmark the Preheat temperature for welding carbon steel files here.

Preheat temperature for welding carbon steel | The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Preheat temperature for welding carbon steel ~ Preheat measuring often is done with Tempilstiks infrared thermometers or other heat-measuring devices. Note Thickness must be 2 x T for a butt weld Calculate Pre-Heat. Recent in- vestigation on laser hybrid welded 10Ni3CrMoV steel showed that at a lower preheat 90C lath martensite and upper bainite that are formed do not have enough time for self tempering. At a higher preheat 120C with enough self-tempering time acicular ferrite is formed along with lath martensite.

1 CEIIW is a preferable index. Also in ASME section I T23 is categorised in the same way as T22 and is required to be pre-heated to a minimum of 400F 205C. STEEL PREHEATING CHART Pre-Heating will eliminate crack formation reduce distortion and prevent shrinkage stresses Metal Metal C Recommended Group Designation Preheat 0F Plain Plain carbon steel Below20 Up to 200 Carbon Plain carbon steel 20-30 200-300 Steel Plain carbon steel 30-45 300-500 Plain carbon steel 45-80 500-800. A high level of accuracy generally is not required for preheating carbon steels.

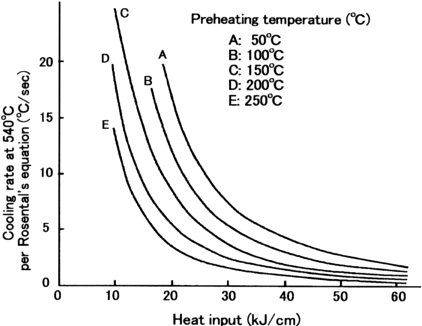

An Article on this subject titled t85 was published 2 in Issue 51 of. Critical preheat temperature for steel H is not higher than 50Ž. The critical cooling rate for a given hardness can be related to the carbon equivalent of the steel. The rate of cooling in the range from 800 C to 500 C has the highest influence in hardenable steels.

EN ISO13916-Tp 90120-CT Preheating temperature Tpwith the range of values from 90C. If water is condensed on material during night prior to welding what would be than the preheat temperature in order to remove moisture. Please comment WPS for welding low carbon mild steel requires preheat of 50C. Hydrogen will eventually disperse from the parent metal within a few days at room temperature or a few hours if held at around 200C.

As shown in Fig. For such materials a suitable range of Weld-preheating shall be specified to avoid rapid cooling that could dangerously affect joint microstructure and properties. For ASTM A709 Grade HPS 70W and ASTM A852 the maximum preheat and interpass temperatures shall not exceed 400F 200C for thicknesses up to 1-12 in 40 mm inclusive and 450F 230C for greater. From the critical cooling rate a minimum preheat temperature can be calculated.

Designation preheating temperature on welding procedure WPS according to EN ISO13916 Example - Temperature. This is a safe approach but it would serve you well to look at one or two other ways to calculate the preheat temperature to make sure you are not adding unnecessary costs to your operation. But it describes the methods factors involved in the determination of preheating requirement and preheat temperature in Annex C. Preheat temperatures vary by the thickness type grade and carbon equivalency of the base material.

Based on the assumption that cracking will not occur if the. BS EN 1011-2 does not have a ready reckoner table for material-wise preheat temperature like other codesstandards such as ASME B313 AWS D11 etc. B Hydrogen Control Method. A preheat of 250F may be recommended when 150F would do.

When the base metal temperature is below 32F 0C the base metal shall be preheated to a minimum of 70F 20C and the minimum interpass temperature shall be maintained during welding. Hydrogen cracking is only possible at room temperature this is why it is also referred to as cold cracking. Min Pre-Heat Temperature C. Preheating a wider area minimizes the risk of colder areas in the material sucking away the heat.

The ASME Code allows up to 16 mm thick tubes T23 to be welded without application of PWHT. Its main value is in determining the minimum heat input and hence minimum weld size that prevents excessive hardening. If preheating is required be sure to do it before any weldingincluding tack weldingtakes place. Although it is important that the work be heated to a minimum temperate it is acceptable to exceed that temperature by approximately 100F 40C.

If you are looking for Preheat Temperature For Welding Carbon Steel you've come to the perfect location. We have 10 graphics about preheat temperature for welding carbon steel adding images, photos, pictures, wallpapers, and much more. In these web page, we additionally have number of images out there. Such as png, jpg, animated gifs, pic art, logo, blackandwhite, translucent, etc.

Although it is important that the work be heated to a minimum temperate it is acceptable to exceed that temperature by approximately 100F 40C. If preheating is required be sure to do it before any weldingincluding tack weldingtakes place. Your Preheat temperature for welding carbon steel photos are available in this site. Preheat temperature for welding carbon steel are a topic that has been searched for and liked by netizens today. You can Get or bookmark the Preheat temperature for welding carbon steel files here.

Its main value is in determining the minimum heat input and hence minimum weld size that prevents excessive hardening. The ASME Code allows up to 16 mm thick tubes T23 to be welded without application of PWHT. Your Preheat temperature for welding carbon steel pictures are ready. Preheat temperature for welding carbon steel are a topic that has been searched for and liked by netizens now. You can Get or bookmark the Preheat temperature for welding carbon steel files here.

Preheating a wider area minimizes the risk of colder areas in the material sucking away the heat. Min Pre-Heat Temperature C. Your Preheat temperature for welding carbon steel image are ready. Preheat temperature for welding carbon steel are a topic that is being searched for and liked by netizens now. You can Download or bookmark the Preheat temperature for welding carbon steel files here.

Hydrogen cracking is only possible at room temperature this is why it is also referred to as cold cracking. When the base metal temperature is below 32F 0C the base metal shall be preheated to a minimum of 70F 20C and the minimum interpass temperature shall be maintained during welding. Your Preheat temperature for welding carbon steel pictures are ready. Preheat temperature for welding carbon steel are a topic that has been searched for and liked by netizens now. You can Get or bookmark the Preheat temperature for welding carbon steel files here.

A preheat of 250F may be recommended when 150F would do. B Hydrogen Control Method. Your Preheat temperature for welding carbon steel images are ready in this website. Preheat temperature for welding carbon steel are a topic that is being hunted for and liked by netizens today. You can Download or bookmark the Preheat temperature for welding carbon steel files here.

BS EN 1011-2 does not have a ready reckoner table for material-wise preheat temperature like other codesstandards such as ASME B313 AWS D11 etc. Based on the assumption that cracking will not occur if the. Your Preheat temperature for welding carbon steel picture are ready in this website. Preheat temperature for welding carbon steel are a topic that has been searched for and liked by netizens now. You can Download or bookmark the Preheat temperature for welding carbon steel files here.

Preheat temperatures vary by the thickness type grade and carbon equivalency of the base material. But it describes the methods factors involved in the determination of preheating requirement and preheat temperature in Annex C. Your Preheat temperature for welding carbon steel picture are ready. Preheat temperature for welding carbon steel are a topic that is being hunted for and liked by netizens now. You can Get or bookmark the Preheat temperature for welding carbon steel files here.

This is a safe approach but it would serve you well to look at one or two other ways to calculate the preheat temperature to make sure you are not adding unnecessary costs to your operation. Designation preheating temperature on welding procedure WPS according to EN ISO13916 Example - Temperature. Your Preheat temperature for welding carbon steel photos are ready. Preheat temperature for welding carbon steel are a topic that has been searched for and liked by netizens today. You can Find and Download or bookmark the Preheat temperature for welding carbon steel files here.

From the critical cooling rate a minimum preheat temperature can be calculated. For ASTM A709 Grade HPS 70W and ASTM A852 the maximum preheat and interpass temperatures shall not exceed 400F 200C for thicknesses up to 1-12 in 40 mm inclusive and 450F 230C for greater. Your Preheat temperature for welding carbon steel images are available in this site. Preheat temperature for welding carbon steel are a topic that is being searched for and liked by netizens today. You can Get or bookmark the Preheat temperature for welding carbon steel files here.

If the posting of this web page is beneficial to our suport by posting article posts of the site to social media accounts that you have such as Facebook, Instagram and others or can also bookmark this blog page with all the title Welding Of Medium High Carbon Steels And Special Steels Education Center Kobelco Kobe Steel Ltd Make use of Ctrl + D for computer system devices with House windows operating-system or Control + D for laptop devices with operating-system from Apple. If you use a smartphone, you can even utilize the drawer menu of this browser you use. Whether its a Windows, Macintosh, iOs or Android operating-system, you'll be in a position to download images utilizing the download button.

Post a Comment

Post a Comment