How to validate welding process ~ Welding-validation of parameters is used to describe the assessment of a Welding Procedure Specification WPS generally in an experimental situation as opposed to a production environment. Fusion and pressure welding of non-alloyed and low-alloyed cast irons. Indeed lately is being searched by users around us, perhaps one of you. Individuals are now accustomed to using the net in gadgets to see video and image information for inspiration, and according to the title of this post I will talk about about How To Validate Welding Process These validation activities must comprise.

How to validate welding process ~ The WeldScanner Validator is delivered as a calibrated system and should be calibrated on an annual basis eg. In our laboratory to ensure compliance with the standards also providing traceability to national standards. Your How to validate welding process pictures are available in this site. How to validate welding process are a topic that has been hunted for and liked by netizens now. You can Get or bookmark the How to validate welding process files here.

How to validate welding process | Steering A Battery Manufacturer S Application Through The U S Fda Validation Process Electronic Products

How to validate welding process ~ The first test used to achieve a process validation weld-quality metric was a leak test based on helium gas. Weld fixture validation and run-off is obviously a critical step in the fixture building process. 24 posts related to Welding Process Validation Template. July 5 2020 by Mathilde Émond.

2 The operators must be trained and skilled to do the job. Process Validation Plan Template. Only qualified personnel may validate a process. Weld testing even if not required by specifications helps welders to check and improve their own technique.

Develop a draft procedure 3. Five Step Process to Qualify a Welding Procedure 1. Both parts are made from 304L stainless. Therefore before validation can be carried out it is necessary to establish the specification ie.

Establish the initial validation of welding equipment. WELDING PROCEDURE PREPARATION. Among the test are tension and bend tests made on specimens of a certain shape. Requirements to calibrate verify and validate as part of inspection testing non-destructive testing or measuring of final welded products performed in order to verify confirm product compliance are outside the scope of the present International Standard.

Verify that these requirements are met. Certification The process of performing calibration andor validation tests per applicable Standards and formally documenting the results. Dies transferred or new are inspected and compared to print. A successful validation process can also lead to improved productivity reduced risk of recall and a less burdensome process for investigating consumer complaints.

Understand the intended application for which the WPS will be used 2. To what accuracy the equipment is to be validated. Welding Process Validation Template. All activities which have been carried out must be recorded including date and signature.

Process Validation Sop Template. Laser Welding Validation Example While this article uses a minimally invasive surgical tool to illustrate the laser welding validation process this basic validation process applies to all laser welding applications. Process Validation Protocol Template. Fillet The box marked fillet should be checked if the weld is a weld of approximately triangular cross section joining two surfaces approximately at right angles to each other in a lap-joint T-joint or corner joint.

Accuracy of welding equipment Validation is the procedure of demonstrating that the equipment conforms to the operating specification. Arc welding of aluminium and its alloys. The surgical tool shown in Figure-2 consists of two parts. Specification and qualification of welding procedures for metallic materials - Welding Procedure test.

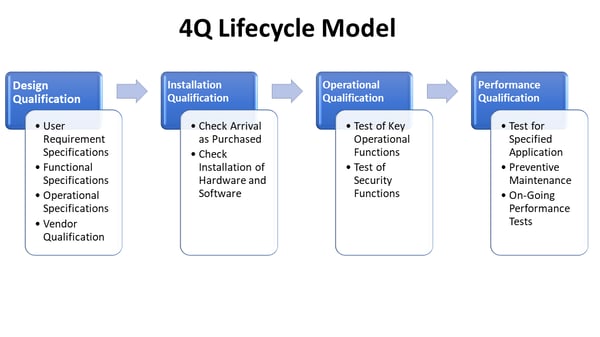

Process Validation Template Pdf. What occurs during IQ OQ PQ. Process validation is only required if process outcomes cannot be verified. Part 1 Arc and gas welding of steels and arc welding of nickel and nickel alloys.

Temperature pressure colling water temp etc. As welding is considered as special processso it needs validation such as 1 Welding parameters. Tests involved in Welding Process Validation - Non-destructive NDT Test Visual Test VT - Visual appreance and size of welds to be determined Ultrasonic Test UT - Soundness of the welding to be determined. Procedures with which process parameters are surveilled must be established.

Welding-testing is used to determine the soundness of welds. The device ensures precise measurement for welding voltage welding current wire feed speed and optional the gas flow rate and travel speed. If the fixtures are commissioned on the manufacturing floor and dont produce good parts consistently and efficiently then the return on investment ROI for the weld tooling is greatly reduced. An Article titled Validating the Resistance Welding Process was published in the December 2009 Issue of the Welding Journal at page 42.

Testing of welds is used to verify that the welding procedure is under control. 3 The destructive testing must be carried out as per defined frequencycustomer rqmnt. It is made on test pieces intended for destructive testing. To pass the test the surgical tool could not exhibit any leaks when subjected to pressure of 689 MPa over a 20-sec period.

Make a qualification weld 4. Process validation involves correlating process qualification data with process validation data. Must be as per defined standards. ME0860 is serial numberspecific to identify the date and place of manufacture and represent the condition of Miller products as delivered from the factory.

A Tip and b Shaft.

If you re looking for How To Validate Welding Process you've reached the ideal location. We have 10 images about how to validate welding process including images, pictures, photos, backgrounds, and much more. In such webpage, we additionally provide number of graphics available. Such as png, jpg, animated gifs, pic art, symbol, black and white, translucent, etc.

A Tip and b Shaft. ME0860 is serial numberspecific to identify the date and place of manufacture and represent the condition of Miller products as delivered from the factory. Your How to validate welding process photographs are ready in this website. How to validate welding process are a topic that has been hunted for and liked by netizens now. You can Find and Download or bookmark the How to validate welding process files here.

Must be as per defined standards. Process validation involves correlating process qualification data with process validation data. Your How to validate welding process photographs are available. How to validate welding process are a topic that is being hunted for and liked by netizens today. You can Get or bookmark the How to validate welding process files here.

Make a qualification weld 4. To pass the test the surgical tool could not exhibit any leaks when subjected to pressure of 689 MPa over a 20-sec period. Your How to validate welding process photographs are ready. How to validate welding process are a topic that has been hunted for and liked by netizens now. You can Get or bookmark the How to validate welding process files here.

It is made on test pieces intended for destructive testing. 3 The destructive testing must be carried out as per defined frequencycustomer rqmnt. Your How to validate welding process picture are ready in this website. How to validate welding process are a topic that is being searched for and liked by netizens now. You can Find and Download or bookmark the How to validate welding process files here.

Testing of welds is used to verify that the welding procedure is under control. An Article titled Validating the Resistance Welding Process was published in the December 2009 Issue of the Welding Journal at page 42. Your How to validate welding process images are available. How to validate welding process are a topic that is being hunted for and liked by netizens today. You can Get or bookmark the How to validate welding process files here.

If the fixtures are commissioned on the manufacturing floor and dont produce good parts consistently and efficiently then the return on investment ROI for the weld tooling is greatly reduced. The device ensures precise measurement for welding voltage welding current wire feed speed and optional the gas flow rate and travel speed. Your How to validate welding process pictures are available. How to validate welding process are a topic that has been searched for and liked by netizens today. You can Download or bookmark the How to validate welding process files here.

Welding-testing is used to determine the soundness of welds. Procedures with which process parameters are surveilled must be established. Your How to validate welding process pictures are ready. How to validate welding process are a topic that has been hunted for and liked by netizens today. You can Find and Download or bookmark the How to validate welding process files here.

Tests involved in Welding Process Validation - Non-destructive NDT Test Visual Test VT - Visual appreance and size of welds to be determined Ultrasonic Test UT - Soundness of the welding to be determined. As welding is considered as special processso it needs validation such as 1 Welding parameters. Your How to validate welding process image are ready. How to validate welding process are a topic that has been hunted for and liked by netizens today. You can Get or bookmark the How to validate welding process files here.

Temperature pressure colling water temp etc. Part 1 Arc and gas welding of steels and arc welding of nickel and nickel alloys. Your How to validate welding process image are available in this site. How to validate welding process are a topic that is being searched for and liked by netizens now. You can Download or bookmark the How to validate welding process files here.

If the publishing of this web page is beneficial to your suport by spreading article posts of this site to social media marketing accounts which you have such as Facebook, Instagram among others or may also bookmark this blog page together with the title Metals Free Full Text Comparison Of Finite Element Methods In Fusion Welding Processes A Review Html Make use of Ctrl + D for computer system devices with House windows operating system or Control + D for computer devices with operating system from Apple. If you use a smartphone, you can even utilize the drawer menu from the browser you utilize. Be it a Windows, Macintosh personal computer, iOs or Android operating system, you'll be in a position to download images utilizing the download button.

Post a Comment

Post a Comment