Welding techniques for battery cells and resulting electrical contact resistance ~ The electric resistance and mechanical strength of the welded contact were measured. A wide spectrum of welding applications including prismatic and cylindrical Li-ion batteries by utilizing longitudinal or torsional welding techniques. Indeed lately has been hunted by consumers around us, perhaps one of you personally. Individuals are now accustomed to using the net in gadgets to see video and image information for inspiration, and according to the name of this article I will talk about about Welding Techniques For Battery Cells And Resulting Electrical Contact Resistance All three methods are tried and proven to function in the production of battery applications.

Welding techniques for battery cells and resulting electrical contact resistance ~ Each of these welding techniques has its own characteristics depending on the material properties and contact geometry. Cell casing and terminal dimensions may constrain possible contact geometries. Your Welding techniques for battery cells and resulting electrical contact resistance image are available in this site. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being searched for and liked by netizens today. You can Get or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

Welding techniques for battery cells and resulting electrical contact resistance | Overlap Joining Of Aluminium And Copper Using Laser Micro Welding With Spatial Power Modulation Springerlink

Welding techniques for battery cells and resulting electrical contact resistance ~ The compared techniques are resistance spot welding laser beam welding and ultrasonic welding. The weld nugget size is usually defined by the electrode tip contact. Contact resistance is an important factor in the first few milliseconds of a weldCombined with bulk resistance the contact resistance value of the workpieces electrodes and their interfaces both cause and affect the amount of heat generated. The current and the heat generation are localized by the form of the electrodes.

In resistance welding contact resistance is a function of the extent to which two surfaces come in contact. Finally the suistriple welding parameter setting ranges were obtained as. Electrical joints with a low contact resistance and a high mechanical strength can be achieved. The weld quality of the joint is an important factor in determining the performance and safety of the battery.

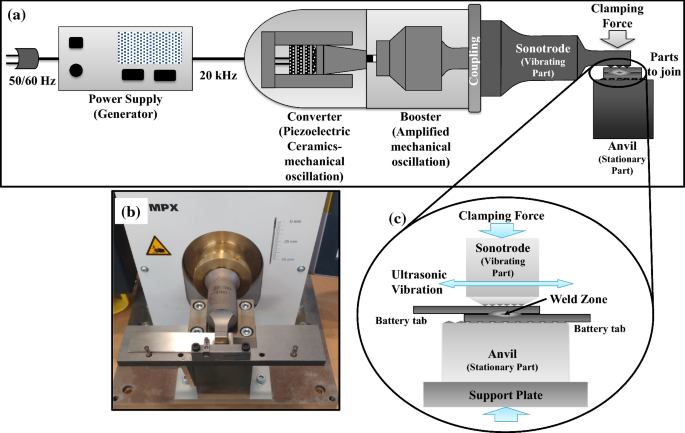

Round cell is done with Telsonic Ultrasonics using the longitudinal or alternatively the torsional welding. Spot welding is a resistance welding process for joining metal sheets by directly applying opposing forces with electrodes with pointed tips. As different welding position sequences for three. Resistance spot ultrasonic or laser beam welding are mostly used for connecting battery cells in the production of large battery assemblies.

This technique works because the heat generated in the work piece is distributed based on where the electrical resistance is. A higher electrode force will reduce contact resistance which in turn will reduce heat at the contact points electrode-to-part and part-to-part interfaces. The joining techniques with application for battery tab interconnects are ultrasonic metal welding resistance spot welding and pulsed TIG spot welding. Cell casing and terminal dimensions may constrain possible contact geometries.

The performance was evaluated in terms of numerous factors such as production cost degree of automation and weld quality. In the penultimate section of this work soldering is compared to welding techniques and press contacts in terms of electrical connection resistances and ultimate tensile force. Owing to the sur-. The resistance spot ultrasonic laser welding micro friction stir blind riveting FSBR micro friction stir forming FSF and micro friction stir welding FSW are the common joining techniques.

To weld different positions it results in structural deformation of the positive battery terminal which directly affects the contact pressure. Although soldering techniques have some significant advantages welding techniques such as spot and laser welding are mostly used within the industrial production of batteries. 1b surfaces irregularities are schematically shown in a magnified portion of the contact interface. In order to highlight the importance of contact resistance we consider two electrically conductive bod-ies which are in contact under an applied force F see Fig.

In common battery assemblies the joint between the battery cell and the current collector cell connector is realized by different welding techniques like spot laser beam or ultrasonic welding. Laser welding with high power fiber laser systems can produce complete battery modules that reach the capacities and cell voltages eg 400 V or 800 V required for electrical vehicles 3. Lap shear and T-peel tests are performed to evaluate the joint strength. For example pouch cells provide detached tabs whereas cells.

An alternative joint for connecting battery cells is a clamped electrical contact. Each of these welding techniques has its own characteristics depending on the material properties and contact geometry. Resistance spot ultrasonic or laser beam welding are mostly used for connecting battery cells in the production of large battery assemblies. Welding techniques for welding batteries.

The contact between the tab and the inner cell casing must be mechanically strong and have low electrical contact resistance. In the cell assembly the bonding of the conductor foils anode - copper and cathode - aluminium with the cell conductors pouch cell or with the contact terminals eg. Resistance spot welding RSW works on the principle of electrical resistance at the mating surfaces when high current passes through them creating localised heating and fusion of materials under pressure. The results presented in this paper show that laser beam welding with continuous wave radiation is a suitable joining process for the electrical connection of 26650 battery cells while avoiding a critical temperature change within the cells.

If you re searching for Welding Techniques For Battery Cells And Resulting Electrical Contact Resistance you've reached the ideal place. We have 10 images about welding techniques for battery cells and resulting electrical contact resistance adding pictures, photos, photographs, wallpapers, and much more. In such web page, we additionally provide number of graphics out there. Such as png, jpg, animated gifs, pic art, symbol, blackandwhite, transparent, etc.

The results presented in this paper show that laser beam welding with continuous wave radiation is a suitable joining process for the electrical connection of 26650 battery cells while avoiding a critical temperature change within the cells. Resistance spot welding RSW works on the principle of electrical resistance at the mating surfaces when high current passes through them creating localised heating and fusion of materials under pressure. Your Welding techniques for battery cells and resulting electrical contact resistance photos are available. Welding techniques for battery cells and resulting electrical contact resistance are a topic that has been searched for and liked by netizens today. You can Find and Download or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

In the cell assembly the bonding of the conductor foils anode - copper and cathode - aluminium with the cell conductors pouch cell or with the contact terminals eg. The contact between the tab and the inner cell casing must be mechanically strong and have low electrical contact resistance. Your Welding techniques for battery cells and resulting electrical contact resistance picture are available in this site. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being hunted for and liked by netizens today. You can Find and Download or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

Welding techniques for welding batteries. Resistance spot ultrasonic or laser beam welding are mostly used for connecting battery cells in the production of large battery assemblies. Your Welding techniques for battery cells and resulting electrical contact resistance picture are ready in this website. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being searched for and liked by netizens now. You can Download or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

Each of these welding techniques has its own characteristics depending on the material properties and contact geometry. An alternative joint for connecting battery cells is a clamped electrical contact. Your Welding techniques for battery cells and resulting electrical contact resistance image are ready in this website. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being hunted for and liked by netizens now. You can Find and Download or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

For example pouch cells provide detached tabs whereas cells. Lap shear and T-peel tests are performed to evaluate the joint strength. Your Welding techniques for battery cells and resulting electrical contact resistance picture are available. Welding techniques for battery cells and resulting electrical contact resistance are a topic that has been hunted for and liked by netizens today. You can Get or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

Laser welding with high power fiber laser systems can produce complete battery modules that reach the capacities and cell voltages eg 400 V or 800 V required for electrical vehicles 3. In common battery assemblies the joint between the battery cell and the current collector cell connector is realized by different welding techniques like spot laser beam or ultrasonic welding. Your Welding techniques for battery cells and resulting electrical contact resistance picture are ready in this website. Welding techniques for battery cells and resulting electrical contact resistance are a topic that has been searched for and liked by netizens now. You can Download or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

In order to highlight the importance of contact resistance we consider two electrically conductive bod-ies which are in contact under an applied force F see Fig. 1b surfaces irregularities are schematically shown in a magnified portion of the contact interface. Your Welding techniques for battery cells and resulting electrical contact resistance pictures are ready. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being searched for and liked by netizens now. You can Get or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

Although soldering techniques have some significant advantages welding techniques such as spot and laser welding are mostly used within the industrial production of batteries. To weld different positions it results in structural deformation of the positive battery terminal which directly affects the contact pressure. Your Welding techniques for battery cells and resulting electrical contact resistance pictures are ready. Welding techniques for battery cells and resulting electrical contact resistance are a topic that is being hunted for and liked by netizens today. You can Get or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

The resistance spot ultrasonic laser welding micro friction stir blind riveting FSBR micro friction stir forming FSF and micro friction stir welding FSW are the common joining techniques. Owing to the sur-. Your Welding techniques for battery cells and resulting electrical contact resistance pictures are ready in this website. Welding techniques for battery cells and resulting electrical contact resistance are a topic that has been hunted for and liked by netizens today. You can Get or bookmark the Welding techniques for battery cells and resulting electrical contact resistance files here.

If the posting of this webpage is beneficial to our suport by spreading article posts of the site to social media accounts which you have such as for example Facebook, Instagram among others or may also bookmark this website page using the title Weldability And Shear Strength Feasibility Study For Automotive Electric Vehicle Battery Tab Interconnects Springerlink Make use of Ctrl + D for laptop or computer devices with House windows operating system or Demand + D for computer devices with operating system from Apple. If you are using a smartphone, you can even use the drawer menu from the browser you use. Be it a Windows, Mac pc, iOs or Android operating-system, you'll be in a position to download images utilizing the download button.

Post a Comment

Post a Comment