Tool design for friction stir welding ~ A cost model is an important tool for product design and material selection. Because it avoids many of the common problems of standard fusion welding Friction Stir Welding FSW is a widely used solid state joining process in a growing number of industries. Indeed lately is being searched by users around us, perhaps one of you. People now are accustomed to using the internet in gadgets to view video and image information for inspiration, and according to the name of this article I will discuss about Tool Design For Friction Stir Welding Material then consolidates into the weld joint.

Tool design for friction stir welding ~ Friction stir welding FSW is a widely used solid state joining process for soft materials such as aluminium alloys because it avoids many of the common problems of fusion welding. Although the outcome of FSW is similar to fusion welding the strength and precision of the weld the process. Your Tool design for friction stir welding photos are available in this site. Tool design for friction stir welding are a topic that is being searched for and liked by netizens now. You can Get or bookmark the Tool design for friction stir welding files here.

Tool design for friction stir welding | Friction Stir Welding

Tool design for friction stir welding ~ Although there is not a standard FSW. However there has never been a standard FSW tool probe shoulder design that has been incorporated into standards and specifications such as BS EN ISO 25239-12020 friction stir welding aluminium or AWS D173D173M2016 specification for friction stir welding of aluminium alloys for aerospace applications. The nib usually threaded and the shoulder in which it is. The effect of flute geometry in tool pins on material flow velocity is investigated by the software ANSYS FLUENT.

The known functional consequences of. E - Design Tool for Friction Stir Welding FSW. Conventional friction stir welding tools. Describes the geometries and operating principles of novel tool designs for friction stir welding FSW butt and lap joints and examines the practical benefits and weld integrity improvements arising from process developments.

The process of friction stir welding is simulated by means of the COSMOS FloWORKS application. Tools for Friction Stir Welding R. In the design of friction stir welding this software is used to determine the result of tool action on the viscoplastic medium. Drawing on experience from manufacturing Friction Stir Welding tools since the invention of the process in 1991 we manufacture tooling for a range of industries and provide advice and support.

Friction stir welding FSW is a solidstate welding process that shows promise in the aerospace industry. The friction stir welding of 15-mm-thick AA6082-T651 extruded flats was performed using three different tool pin profiles ie CL CLR and CTFL up to a height of 6 mm from the pin tip. In Friction stir welding the tool geometry plays a fundamental role to obtain suited microstructures in the weld and the heat affected zone. DESIGN FOR MANUFACTURING FOR FRICTION STIR WELDING by HARISH BAGAITKAR A THESIS Presented to the Faculty of the Graduate School of the MISSOURI UNIVERSITY OF SCIENCE AND TECHNOLOGY In Partial Fulfillment of the Requirements for the Degree.

Once the material becomes plasticized the tool traverses along a weld line to bond the two materials together Plasticized material is deformed around the tool and is forged into place by the substantial downward axial force of the tool shoulder. Improved breaking and mixing of the oxide layer and more efficient heat generation yielding higher welding speeds and of course enhanced quality. A new system of experimentation has been used to quickly make and screen new tool designs. An efficient and effective cost estimation tool is necessary for early design evaluation.

AA-6082 is an excellent corrosion resistance. Keywords-Friction stir weldingTool Design Microstructure and Mechanical properties. INTRODUCTION The need of joining dissimilar materials often arises in industrial application due to demand for reduced weight and improved performance from engineering structure. Of friction stir welding.

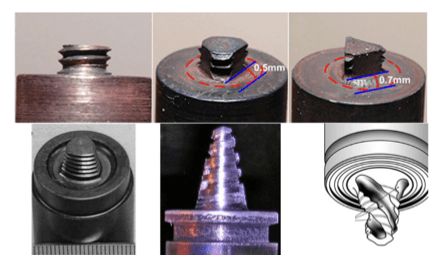

1 Schematic drawing of Friction Stir Welding 11 Work Piece and Tool Material FSW work pieces are of AA-6082-T6 having dimensions of 300755 mm cross section. In order to improve material flow behavior during friction stir welding and avoid root flaws of weld a tool with a half-screw pin and a tool with a tapered-flute pin are suggested. When they rotate in contact with the base material it creates frictional heat that produces a plasticized region around the tool. Friction stir welding can be performed on a variety of joint configuration including butt joint lap joint and T joint 1.

The formation and elimination of weld defects for different tool pin profiles microstructural features and mechanical properties across the weld depth were studied. It is also known as structural alloy. Why Pin tool design is critical in Friction Stir Welding. The tool used in Friction Stir Welding consists of a protruding pin that is plunged into the workpieces and the larger concentric shoulder maintained on the surface of the joint.

Friction stir welding FSW is a relatively new technique for welding that uses a cylindrical pin or nib inserted along the weld seam. In this paper cost estimation models that estimate the production cost for Metal Inert Gas MIG Friction Stir FS and Friction Stir Spot FSS welded joints are presented. The tool is designed by means of SolidWorks software with the creation of 3D models of the tools. The results can be categorised according to 1 pin features 2 shoulder features and 3 tool dimensions.

Optimising tool geometry to produce more heat or achieve more efficient stirring offers two main benefits. Triton Tooling works closely with a variety of clients in the Friction Stir Welding industry including TWI Ltd to provide bespoke FSW tooling to worldwide customers. Tools Welding tool design is critical in FSW. After conducting a literature review friction stir tools were designed to optimize material flow around the tool.

Ideal for mechanised welding. Tool design has been an active area of research for single shoulder type CFSW tools.

If you re looking for Tool Design For Friction Stir Welding you've arrived at the right location. We ve got 10 graphics about tool design for friction stir welding including images, pictures, photos, wallpapers, and much more. In these web page, we also provide number of graphics out there. Such as png, jpg, animated gifs, pic art, symbol, blackandwhite, transparent, etc.

Tool design has been an active area of research for single shoulder type CFSW tools. Ideal for mechanised welding. Your Tool design for friction stir welding photos are ready. Tool design for friction stir welding are a topic that has been hunted for and liked by netizens today. You can Get or bookmark the Tool design for friction stir welding files here.

After conducting a literature review friction stir tools were designed to optimize material flow around the tool. Tools Welding tool design is critical in FSW. Your Tool design for friction stir welding images are ready. Tool design for friction stir welding are a topic that has been hunted for and liked by netizens now. You can Get or bookmark the Tool design for friction stir welding files here.

Triton Tooling works closely with a variety of clients in the Friction Stir Welding industry including TWI Ltd to provide bespoke FSW tooling to worldwide customers. Optimising tool geometry to produce more heat or achieve more efficient stirring offers two main benefits. Your Tool design for friction stir welding photographs are available. Tool design for friction stir welding are a topic that has been searched for and liked by netizens now. You can Download or bookmark the Tool design for friction stir welding files here.

The results can be categorised according to 1 pin features 2 shoulder features and 3 tool dimensions. The tool is designed by means of SolidWorks software with the creation of 3D models of the tools. Your Tool design for friction stir welding photos are ready in this website. Tool design for friction stir welding are a topic that is being hunted for and liked by netizens now. You can Get or bookmark the Tool design for friction stir welding files here.

In this paper cost estimation models that estimate the production cost for Metal Inert Gas MIG Friction Stir FS and Friction Stir Spot FSS welded joints are presented. Friction stir welding FSW is a relatively new technique for welding that uses a cylindrical pin or nib inserted along the weld seam. Your Tool design for friction stir welding picture are ready. Tool design for friction stir welding are a topic that has been hunted for and liked by netizens now. You can Download or bookmark the Tool design for friction stir welding files here.

The tool used in Friction Stir Welding consists of a protruding pin that is plunged into the workpieces and the larger concentric shoulder maintained on the surface of the joint. Why Pin tool design is critical in Friction Stir Welding. Your Tool design for friction stir welding pictures are ready. Tool design for friction stir welding are a topic that is being searched for and liked by netizens now. You can Get or bookmark the Tool design for friction stir welding files here.

It is also known as structural alloy. The formation and elimination of weld defects for different tool pin profiles microstructural features and mechanical properties across the weld depth were studied. Your Tool design for friction stir welding photographs are ready in this website. Tool design for friction stir welding are a topic that has been searched for and liked by netizens now. You can Get or bookmark the Tool design for friction stir welding files here.

Friction stir welding can be performed on a variety of joint configuration including butt joint lap joint and T joint 1. When they rotate in contact with the base material it creates frictional heat that produces a plasticized region around the tool. Your Tool design for friction stir welding photos are available in this site. Tool design for friction stir welding are a topic that is being hunted for and liked by netizens today. You can Download or bookmark the Tool design for friction stir welding files here.

In order to improve material flow behavior during friction stir welding and avoid root flaws of weld a tool with a half-screw pin and a tool with a tapered-flute pin are suggested. 1 Schematic drawing of Friction Stir Welding 11 Work Piece and Tool Material FSW work pieces are of AA-6082-T6 having dimensions of 300755 mm cross section. Your Tool design for friction stir welding photos are ready. Tool design for friction stir welding are a topic that has been hunted for and liked by netizens now. You can Find and Download or bookmark the Tool design for friction stir welding files here.

If the posting of this internet site is beneficial to your suport by sharing article posts of this site to social media accounts which you have such as for example Facebook, Instagram and others or may also bookmark this website page with the title Initial Parts Of Tool In Friction Stir Welding 12 16 Download Scientific Diagram Work with Ctrl + D for computer devices with Windows operating system or Order + D for computer devices with operating-system from Apple. If you use a smartphone, you can also use the drawer menu from the browser you utilize. Be it a Windows, Apple pc, iOs or Android os operating-system, you'll be in a position to download images using the download button.

Post a Comment

Post a Comment