How to weld aluminum block ~ A MIG welder for Aluminum will do this automatically when. Inspect the surface of the aluminum to ensure that it is clean. Indeed recently is being searched by users around us, maybe one of you. Individuals now are accustomed to using the internet in gadgets to view image and video data for inspiration, and according to the name of the post I will discuss about How To Weld Aluminum Block I was figuring on getting a piece of flat stock 14 and making a patch to cover the hole then welding the perimeter of the patch to the block.

How to weld aluminum block ~ Then set the amperage of your welder aim at the aluminum pieces and press the button on the torch. He cut out 14 inch of material to weld the crack at its root so there was at the very least 14 of material welded onto this it looks like it was ground down as well. Your How to weld aluminum block images are ready in this website. How to weld aluminum block are a topic that has been searched for and liked by netizens today. You can Download or bookmark the How to weld aluminum block files here.

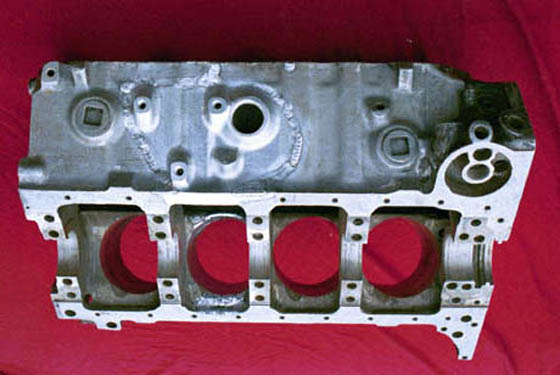

How to weld aluminum block | Aluminum Engine Block Repair Build And Tune

How to weld aluminum block ~ Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal. One of the keys to welding this crack together is that you have to spend a good amount of time making sure the crack is free from paint rust and liquids. I can weld it from both sides since I will probably take the complete engine apart. To stop the crack make sure you drill a very small hole at the base of it to keep it from spreading.

Aluminum will start to melt at 1200deg Fahrenheit but the brazing rod will melt at around 700deg so we want to get the aluminum hot enough to melt the rod without melting the tubing. Its best to use a filler rod that is similar to the engine block alloy to achieve a stronger weld. After a little more digging Ive found the block to be made of alusil which has 30 silicon and 70 aluminum after boring the cylinders they etch the cylinder to expose the silicon in the cylinder which basically creates a surface like the nikasil with the ability to retain oil and high wearability. That little hunk of metal should look red with anger once you pull it out.

A MIG welder welding Aluminum correctly spray transfers the wire into the weld. To weld aluminum clamp the aluminum pieces together tightly and use a propane torch to preheat them to a temperature between 300F and 400F. Let the alcohol dry before applying the JB Weld epoxy. Getting the tubing hot enough may take 4 to 5 minutes.

Wipe the degreasing agent from the surface of the damaged aluminum with a clean rag. Does J-B Weld Work On Aluminum Engine Block. However with the evolution of high-power good-beam-quality carbon dioxide CO 2 lasers and the advent of high-power high-brightness solid-state fiber-delivered lasers coupling the energy into aluminum is no longer an issue. Also if it sJUST a seep drill the hole clen it a LOT with brake clean and get some motoseal from the parts store and seal it with that.

Use a stainless steel wire brush used exclusively for aluminum to remove surface oxides. Clamp up the tubing and start heating the aluminum with a propane torch. Repeat steps one and two if you notice that the aluminum is not clean. For those times when solid strong welds are needed over aesthetically looking beads.

Argon gas or Argon Helium mix is the shielding gas. In the past aluminums high reflectivity was a problem for laser welding. The hole is 1x2. You can see it is in a window only and nothing too involved.

Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal. Use a solvent such as acetone or a mild alkaline solution like a strong soap to remove any oil grease and water vapor from the aluminums surface. When welding thicker metal or a casting pulling the gun backwards toward you produces deeper penetration. When furnace welding the block itself heats up to 1000-1400 degrees Fahrenheit.

Aluminum is simpler since you can TIG weld it. The voltage is increased Aluminum wire is used and. From what it looks like and what Ive been told he used a TIG-pulse welding configuration and laid pass after pass only letting the block air cool to room temperature. Sure all welders want the stack of dimes look but its not always possi.

The key to aluminum welding. Because aluminums properties vary greatly from steel working with the material can present some unique challenges such as distortion and sensitivity to heat input. The period being the drill point. After cleaning the crack with a wire brush you should wipe it down with rubbing alcohol.

That does work its case sealant for aluminum cases very similar to 1304. I have fixed a ton of cast and billet aluminum blocks and headsno mater what process you use the weld area will loose the original heat treati have a Miller aerowave tig welder and it welds so hot and the arc profile is such that you get killer penetration with no pre heat The less heat you have to use the less of an area that you loose the heat treat and less change it will warp I did a BAE billet block. When welding thin aluminum it usually works best to hold the gun about 35 degrees to the surface and move it forward. I have welded aluminum before.

Aluminum in its pure form is a relatively soft metal that has many uses but which requires the addition of alloys to increase its strength. This means that minute particles of the Aluminum welding wire is sprayed into the weld puddle.

If you are searching for How To Weld Aluminum Block you've come to the perfect location. We have 10 images about how to weld aluminum block adding pictures, photos, photographs, backgrounds, and more. In such web page, we also provide number of images out there. Such as png, jpg, animated gifs, pic art, logo, black and white, translucent, etc.

This means that minute particles of the Aluminum welding wire is sprayed into the weld puddle. Aluminum in its pure form is a relatively soft metal that has many uses but which requires the addition of alloys to increase its strength. Your How to weld aluminum block image are ready in this website. How to weld aluminum block are a topic that is being hunted for and liked by netizens now. You can Find and Download or bookmark the How to weld aluminum block files here.

I have welded aluminum before. When welding thin aluminum it usually works best to hold the gun about 35 degrees to the surface and move it forward. Your How to weld aluminum block pictures are available in this site. How to weld aluminum block are a topic that has been hunted for and liked by netizens today. You can Download or bookmark the How to weld aluminum block files here.

I have fixed a ton of cast and billet aluminum blocks and headsno mater what process you use the weld area will loose the original heat treati have a Miller aerowave tig welder and it welds so hot and the arc profile is such that you get killer penetration with no pre heat The less heat you have to use the less of an area that you loose the heat treat and less change it will warp I did a BAE billet block. That does work its case sealant for aluminum cases very similar to 1304. Your How to weld aluminum block images are available. How to weld aluminum block are a topic that has been searched for and liked by netizens now. You can Find and Download or bookmark the How to weld aluminum block files here.

After cleaning the crack with a wire brush you should wipe it down with rubbing alcohol. The period being the drill point. Your How to weld aluminum block image are available. How to weld aluminum block are a topic that is being searched for and liked by netizens now. You can Find and Download or bookmark the How to weld aluminum block files here.

Because aluminums properties vary greatly from steel working with the material can present some unique challenges such as distortion and sensitivity to heat input. The key to aluminum welding. Your How to weld aluminum block photographs are ready in this website. How to weld aluminum block are a topic that has been searched for and liked by netizens now. You can Download or bookmark the How to weld aluminum block files here.

Sure all welders want the stack of dimes look but its not always possi. From what it looks like and what Ive been told he used a TIG-pulse welding configuration and laid pass after pass only letting the block air cool to room temperature. Your How to weld aluminum block photos are available in this site. How to weld aluminum block are a topic that is being searched for and liked by netizens today. You can Find and Download or bookmark the How to weld aluminum block files here.

The voltage is increased Aluminum wire is used and. Aluminum is simpler since you can TIG weld it. Your How to weld aluminum block pictures are available. How to weld aluminum block are a topic that has been hunted for and liked by netizens today. You can Get or bookmark the How to weld aluminum block files here.

When furnace welding the block itself heats up to 1000-1400 degrees Fahrenheit. When welding thicker metal or a casting pulling the gun backwards toward you produces deeper penetration. Your How to weld aluminum block pictures are ready. How to weld aluminum block are a topic that has been searched for and liked by netizens today. You can Find and Download or bookmark the How to weld aluminum block files here.

Use a solvent such as acetone or a mild alkaline solution like a strong soap to remove any oil grease and water vapor from the aluminums surface. Ad High Performance Wide Range Structural Adhesives Bonding Plastic and Metal. Your How to weld aluminum block pictures are available. How to weld aluminum block are a topic that is being hunted for and liked by netizens today. You can Get or bookmark the How to weld aluminum block files here.

If the posting of this web site is beneficial to our suport by posting article posts of this site to social media accounts you have such as Facebook, Instagram and others or can also bookmark this blog page using the title How To Weld Aluminum Australian General Engineering Vietnam Metal Fabrication Vietnam Use Ctrl + D for personal computer devices with House windows operating system or Order + D for laptop devices with operating system from Apple. If you use a smartphone, you can even utilize the drawer menu in the browser you utilize. Whether its a Windows, Apple pc, iOs or Google android operating system, you'll be able to download images utilizing the download button.

Post a Comment

Post a Comment